Cooling products

Integrating materials, components and technologies from Grupporeco sister companies, Reco Polska is producing the most recent technologies, satisfying customer’s requirements with process optimization, high quality, flexibility and competitiveness.

All the products comply with European regulations and general Industry standards (ff applicable and where necessary).

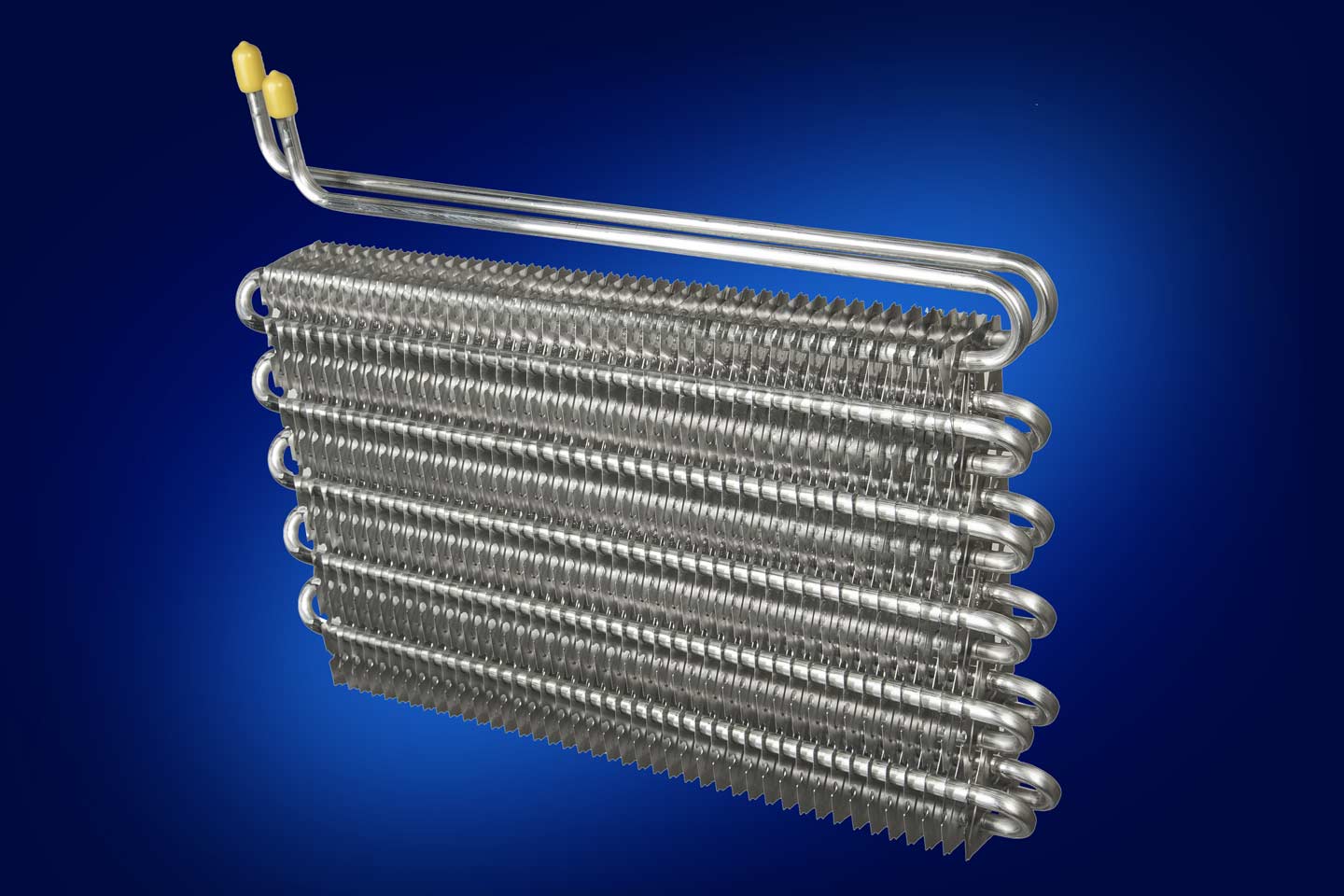

FIN-ON-TUBE (FoT) HEAT EXCHANGERS

Reco Polska continuous Fin-on-Tube Heat Exchanger coils are made from a single extruded aluminium tube. No joints means no hairpins, no return bends, no brazing and no leaks. This provides higher quality, fewer warranty claims and increased value for the customer. Suitable for a wide range of refrigerants, this technology delivers superior heat transfer performance with a lighter, more cost effective solution than the traditional copper tube.

Grupporeco’s highly automated production process ensure maximum contact between tube and fin by means of a collar designed for interference mechanical-fit. This maximizes heat transfer between primary and secondary surface areas of the heat exchanger and creates a highly efficient battery.

Global demands to reduce energy consumption and market trends mean that the traditional “direct cool” technology solutions are being superseded by “dynamic” forced-air solutions. The main applications of the aluminium fin-on-tube heat exchangers are:

• DOMESTIC FREEZER

“No-Frost” Freezer Evaporator for Full or Partial NF Appliances

• DOMESTIC FRIDGE

Dynamic, Forced-Air Fridge Compartments

• PROFESSIONAL COOLERS

Glass Door Ice-Cold-Marchandisers (ICM’s)

• DRYER

“Evaporator” and “Condenser” Heat Exchangers for Laundry Heat Pump Dryers, with optimized high-density fin pitch.

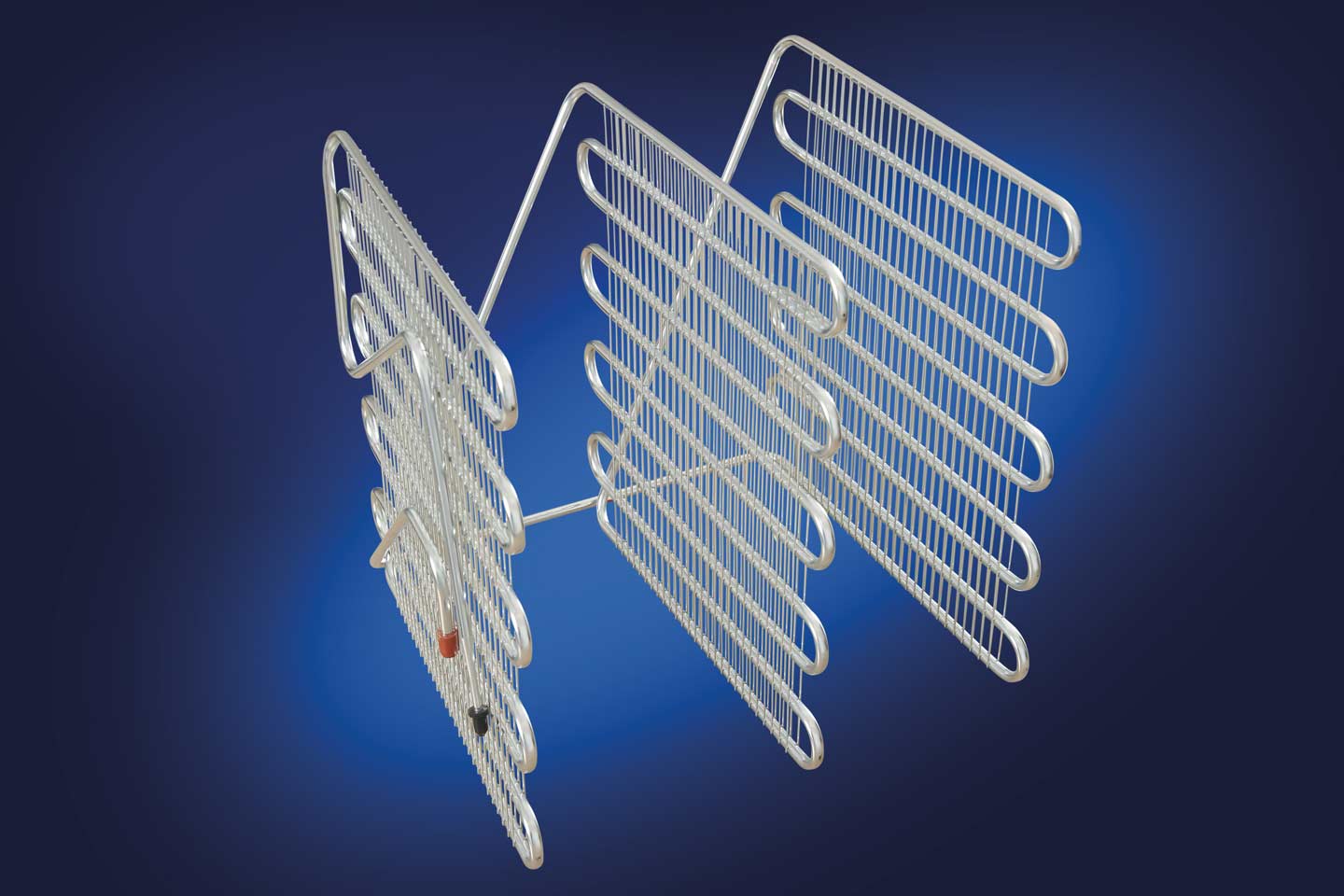

WIRE-ON-TUBE (WoT) EVAPORATORS

Reco Polska is the leading European supplier for domestic and professional appliance application. The design and the “Mono-Tube” process, which provides a single tube solution with no joints for 3 shelf systems, is a Grupporeco’s patent.

We have the ability to supply “evaporator only” or “full assemblies” including the suction line heat exchanger and other tube connections as required. Up to 10-shelf WoT systems are available to suit the number of compartments within the freezer. Flexibility in design for “tube passes” and “number of wires” per shelf, offers a highly flexible and effective solution to optimize cost and energy performance. Zinc and lacquer coating provides high quality and satisfies corrosion resistance requirements. Polyamide coating is available when used within a fridge evaporator application.

The steel Wire-on-Tube evaporator continues to offer a high performance solution for “direct cool” refrigeration freezer systems:

• DOMESTIC FREEZER

Direct cool freezer evaporator, SD and combi fridge freezers

• PROFESSIONAL FREEZER

Single door ICM’s and commercial freezers

• FRIDGE EVAPORATOR

Single shelf within a dynamic-air flow system

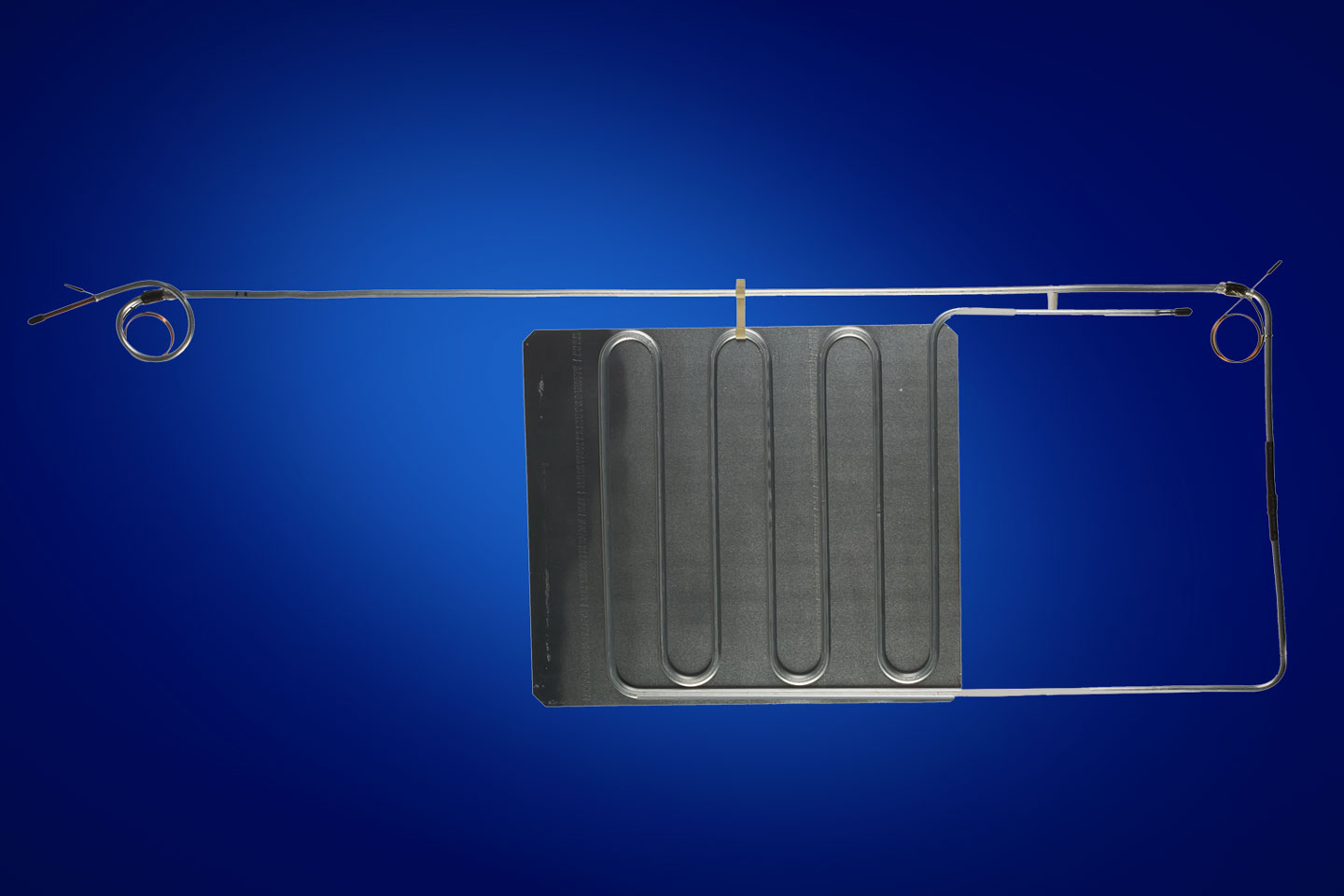

SERPENTINE AND PLATE-ON-TUBE (PoT) FRIDGE EVAPORATORS

Using Arotubi 1070 Aluminium Tubes, Reco Polska offers various fridge evaporator solutions for static refrigerator cooling within direct-cool, no-frost or hybrid appliances. Tubes are flattened to an oval cross-section to maximize heat transfer between tube and plate. The aluminium serpentine can be supplied separate or as part of a “plate-on-tube” assembly.

Capillary can be added to the suction line to create the heat exchanger and provide the “full assembly” solution if required. Solution can incorporate copper connector for compressor connection.

- Single aluminium mono-tube design solution

- Aluminium suction tube OD 6.8 mm x thickness 0.60 mm

- Aluminium plate 0.30 mm thickness

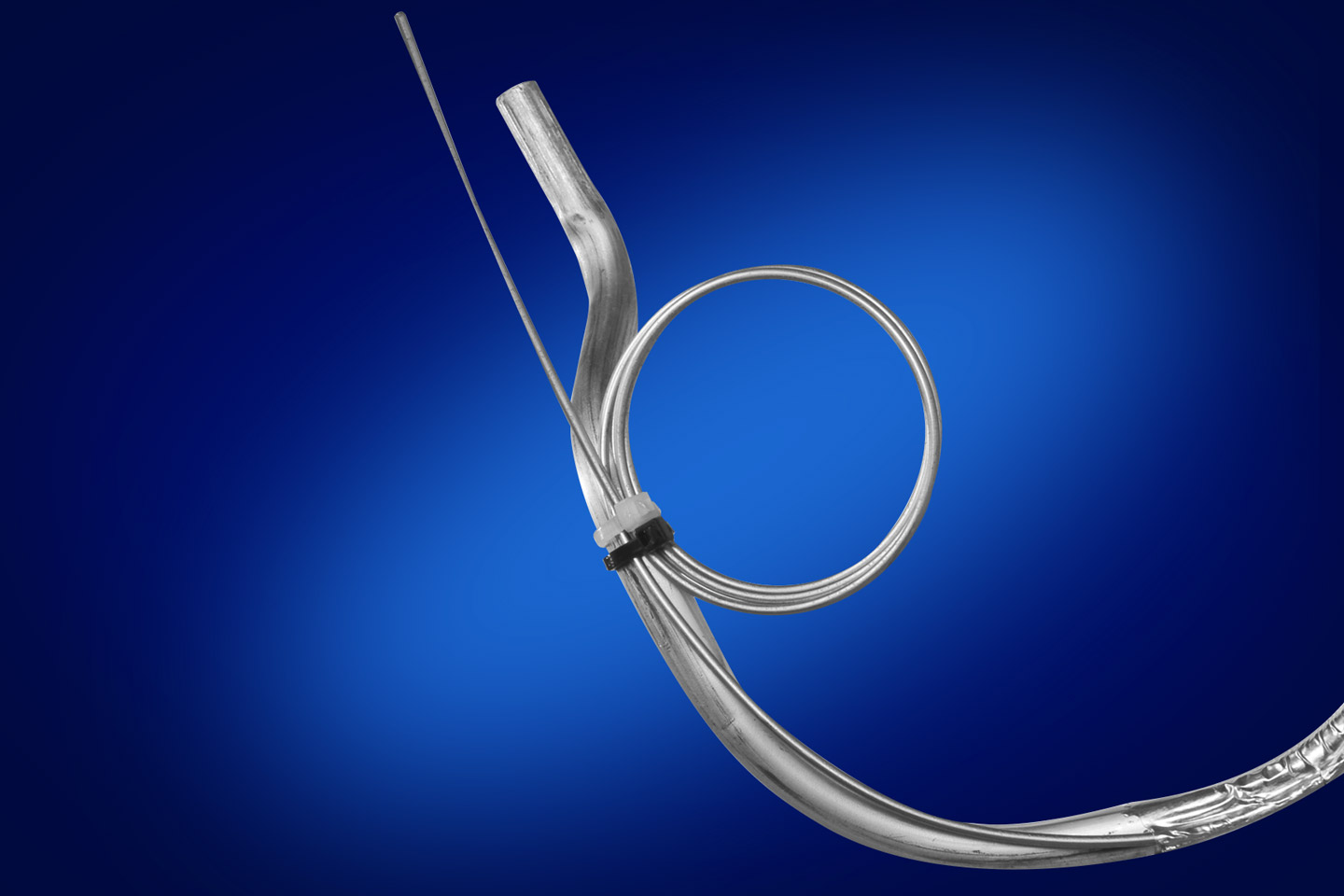

SUCTION LINE HEAT EXCHANGERS (SLHX)

Using Grupporeco/Arotubi patented “Aluminium Capillary” technology – Reco Polska is the only producer who can offer European OEM’s 100% All aluminium suction line heat exchanger solutions. This products is a very precise solution able to avoid any corrosion issue rising because of the aluminum-copper galvanic effect. The aluminium capillary is the critical control device in the cooling system, designed to set the mass flow-rate of the refrigerant.

Copper “connectors” can be designed into the solution if required by the customer; in such case Cu-Al connections can be protected with specific sleeves to ensure corrosion risk is eliminated and quality standards maintained. Various tube bending in 2D and 3D form can be maintained by automated bending equipment.

- Aluminium 1070 alloy suction tube OD 6 mm | 6.8 mm | 8.0 mm x thickness 0.60 mm

- Aluminium capillary OD 1.90 mm x ID x length to satisfy specified mass flow-rate

- Mass flow-rate: +/- 5% [litres per minute @10 bar]

- Aluminium adhesive tape

COOLING PRODUCTS BROCHURE

Download the cooling products general brochure.

Other products

Metal wire

our products of excellence

Aluminium tubes

our products of excellence